What to Consider When Picking A Vibration Isolator

How to Choose the Right Isolator

If you need assistance determining what vibration isolator you should use, there are a few elements you should know before beginning your search. The right isolator for your equipment will be able to handle the load that your equipment produces, fit the space and support any special requirements that may be unique to your equipment or industry.

Learn what factors to consider when selecting a vibration isolator for your application.

How to Pick the Right Vibration Isolator

Picking the right isolator can be a difficult process for demanding applications and industries with highly specific requirements. You need to choose one that will produce excellent isolation performance without affecting the function of the rest of your system.

When it comes to choosing the right isolator for your application, it’s important to understand the difference between vibration isolation and vibration damping. The terms are often used interchangeably, but they are different concepts:

- Damping: Vibration damping is the process of dissipating vibration energy by absorbing and redirecting incoming vibrations into heat.

- Isolation: Vibration isolation limits the level of vibration transmitting into other parts of a system. For example, an isolator can reduce the intensity vibrations in a handheld tool felt in the hand of the operator. Isolators can contain damping elements, but they are not strictly damping devices themselves.

You should also consider whether you will need an active or passive isolation solution. An active system has the ability to sense incoming vibration and create its own force to “cancel out” incoming vibrations, while a passive system’s performance characteristics that determine its isolation and damping performance are set at the time of manufacture. Each system has advantages and disadvantages depending on your application.

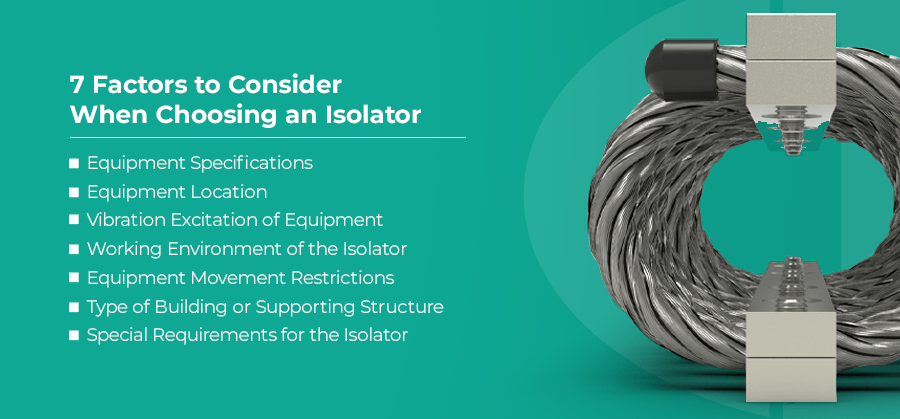

7 Factors to Consider When Choosing an Isolator

The right isolating material for your isolator depends on a system’s ambient conditions and loads. For example, although a high damping solution would provide more control in the region of resonance, isolation performance at higher disturbing frequencies will suffer due to the higher force generated by the damping element. Rubber isolators with increased damping often suffer from high dynamic stiffness, making it difficult to account for the varying performance with varying frequency when selecting the isolator.

Wire rope isolators simultaneously reduce vibration and shock levels, making them highly cost-effective. However, the right isolator depends on the nature of your application.

Here are seven important factors for choosing the correct isolator.

1. Equipment Specifications

It’s important to know your equipment’s unique requirements before choosing an isolator. Some key specifications to keep in mind include:

- Disturbing frequency: Determine the main frequencies of the vibration you wish to isolate. For most types of reciprocating/rotating equipment, the manufacturer likely specifies this range in the operator’s manual. For cases where you have two or more disturbing frequencies, focus on the lowest one.

- Natural isolator frequency: Calculate the minimum natural frequency needed to isolate the vibration is essential for ensuring proper system performance. Choosing an isolator with too high of a natural frequency can amplify vibrations rather than reduce them.

- Vibration Input: How much vibrating force does your equipment produce? Measure this force or check the manufacturer’s specifications to ensure you know the correct range.

2. Equipment Location

Where your equipment is located and the kind of structural support it has can impact which isolator is right for your system. Is your equipment located in the basement or on the roof? Is it mounted on concrete slabs, or do you have rubber mounts? Can the isolator fit into the space without problems? These questions are key considerations for determining which isolator to use.

3. Vibration Excitation of Equipment

All types and directions of vibration should be considered. Equipment and environments often generate vibration in multiple directions simultaneously. For example, the rotational frequency forces and couples resulting from reciprocating masses may need to be considered when deciding which isolator is best for your system. These factors directly determine your system’s isolation requirements.

For instance, it’s important to know whether you are trying to isolate vertical or horizontal vibration. The isolator you choose must be able to handle a load in that direction. This specification will significantly narrow down your list of possible isolators.

4. Working Environment of the Isolator

The environmental factors that will affect the isolator are extremely important considerations for determining the best isolator for your application.

Temperature is the most important environmental factor because elastomeric isolators tend to perform differently in response to different temperatures. In general, elastomeric materials stiffen in lower temperatures and soften at high temperatures. The extent to which this fluctuation affects isolator performance will vary depending on the chosen material.

Fluid exposure is another important factor to consider, if applicable. The level of fluid exposure can impact your isolator, so determine whether your isolator will experience occasional splashes or full immersion.

5. Equipment Movement Restrictions

Your equipment’s installation type is important for choosing the right isolator. A stationary device will usually require a much simpler solution than a mobile one.

For example, a moving vehicle experiences significantly more intense vibration than a stationary vibrating machine in a factory. A captive isolator would be strongly recommended to keep the system intact even when driving over harsh terrain.

6. Type of Building or Supporting Structure

The type of building as well as its intended use can significantly impact which isolator is right for you. Different types of buildings have different isolation requirements based on their purpose — for example, a manufacturing plant will have significantly different requirements from a hospital.

Consider how critical a quiet or reduced-vibration environment is for your setting. Will employees be in direct contact with vibrating equipment? Would noise affect customers or patients? Keep these questions in mind as you search for the right model.

7. Special Requirements for the Isolator

Consider any unique characteristics of your system, such as:

- Varying installation conditions: Will this piece of equipment be subjected to a wide variety of environments? Especially true for field equipment, its important to consider the variety, severity, and frequency of different environments when choosing an isolation system.

- Infrequent or rare dynamic loads: Examples would be wind loading, seismic events, or for outdoor applications, increased static load due to the accumulation of snow or ice. These events should be considered to ensure that the isolation system can sustain them. The requirement of whether or not the isolation system needs to maintain a certain level of performance or simply not fail must be considered in each unique case.

- Additional externally applied forces: Are there any other environmental forces you may need to account for? For example, you may have a high-power fan blowing near the system that could impact vibrations. In multi-use buildings with different types of occupants, unexpected vibration demands often arise. For instance, a medical office may discover that they require isolation for a sensitive device because of fitness facility directly below them.

Investing in a custom isolation solution can be advantageous for your application because it can address all the unique requirements of your system without sacrificing performance and quality.

Vibration Isolation Solutions from IDC

IDC offers a standard line of vibration isolation solutions for all industries and can also custom engineer designs to meet your exact wire rope isolator specification. Some of our most popular wire rope isolation products include:

- M-Series: Our M-Series wire rope isolators feature rugged, fail-safe construction for a versatile, cost-effective vibration mitigation solution.

- SB-Series: Our SB-Series wire rope isolators contain a more compact design with shorter bars to function in a limited space.

- SM-Series: Our SM-Series wire rope isolators use an S-shaped design that delivers superior support, balance and vertical stability.

- XM-Series: Our XM-Series wire rope isolators have a symmetrical X-shape design that provides vertical strength and torsional resistance for lighter loads.

Trust IDC to Help You Choose the Right Isolator for the Job

You can rely on IDC’s unparalleled knowledge and expertise to help you find the best isolation solutions for your industry and application. Browse our selection of stainless steel wire rope isolators or contact us for guidance on what vibration isolator is best for your needs.

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More