The Role of Wire Rope Isolators in Aerospace Applications

The aerospace industry operates in an environment where vibration, shock, and extreme temperatures are unavoidable. From launch vehicles and satellites to manned aircraft and ground-based support systems, nearly every subsystem is exposed to dynamic mechanical forces. For critical aerospace equipment to remain operational and reliable, effective vibration isolation is not just beneficial—it’s essential. Among the most trusted components in this space are wire rope isolators.

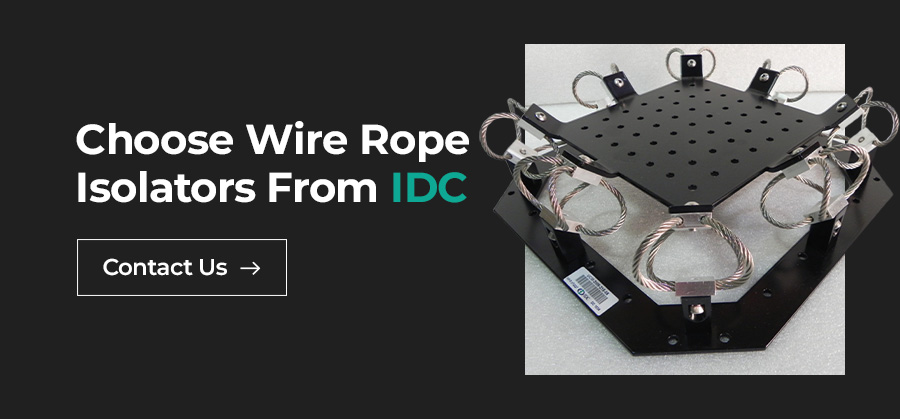

What Are Wire Rope Isolators?

Wire rope isolators are passive, all-metal devices made of stainless-steel cable threaded between metal retaining bars in a helical loop pattern. This unique design allows them to flex in all directions, absorbing energy from shock and vibrations while maintaining structural integrity under a wide range of environmental conditions.

Unlike rubber or elastomeric isolators, wire rope isolators perform reliably in high and low temperatures, resist corrosion, and do not degrade over time. Their mechanical simplicity means they require no maintenance and can endure millions of cycles with consistent performance.

Applications in Aerospace

Wire rope isolators are used in a variety of aerospace applications:

- Avionics and navigation systems: Protects sensitive electronics from in-flight vibration and G-forces

- Satellite enclosures and payloads: Ensures delicate components are protected during launch, re-entry, and transportation

- Ground support and launch equipment: Reduces vibration transfer to control systems and instrumentation

- Unmanned aerial systems (UAS): Prevents interference with optics, sensors, and communications payloads

- Transportation of sensitive aerospace equipment: Maintains equipment integrity during over-the-road, rail, ocean, or air transport by mitigating vibration, impact, and shock loads

Whether used onboard the aircraft, during transport, or in support infrastructure, wire rope isolators play a vital role in maintaining system reliability and mission readiness.

Why Engineers Choose Wire Rope Isolators

- Multidirectional isolation: Ideal for complex dynamic environments like space launches or flight turbulence

- Wide temperature range: Performs well in extreme heat or cold without degradation

- No material creep or fatigue: Withstands long-term use in vibration-heavy environments

- Compact form factor: Fits into tight spaces without compromising load-bearing capability

- Large deflection capabilities: Provides superior shock attenuation and energy dissipation under sudden or extreme impact conditions

IDC offers custom-engineered wire rope isolators tailored to aerospace specs, including custom mount geometries, load ratings, and materials that meet aerospace standards. Partnering early with IDC allows aerospace OEMs to integrate reliable isolation from the beginning, protecting sensitive systems from costly failure.

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More