What is Shock Isolation?

What is Shock Isolation and Why is it Important?

Shock requires management in several industries, particularly in complex mechanical systems. Reducing the severity and effects of shock is critical to human and equipment safety. Shock isolation systems can mitigate the damage caused by sudden energy pulses in many applications, including aerospace, transportation, military and defense.

What Is Shock and What Causes It?

Shock is a transient condition where a single impulse of energy is transmitted to a system with significant acceleration in a short period. It requires a sharp, sudden change in velocity, like kicking a ball or dropping something on the ground. Quantification of the energy in a shock pulse can be defined by acceleration, velocity or displacement time steps.

Impact Shock vs. Vibrations: What's the Difference?

Understanding the differences in shock vs. vibration is essential to provide adequate isolation. Vibration is typically lower in amplitude and duration when an object oscillates around a point of equilibrium. It can be periodic or random. Shock is a sudden burst of energy exerted onto a system characterized by high magnitude and short duration.

While these actions differ, vibration is often present with shock. A burst of energy, like hitting something with a hammer, results in powerful vibration forces that disrupt an object beyond the point of impact. Shock and vibration isolation often overlap, but understanding the differences is critical when mitigating the two phenomena.

What Is Shock Isolation and How Does It Work?

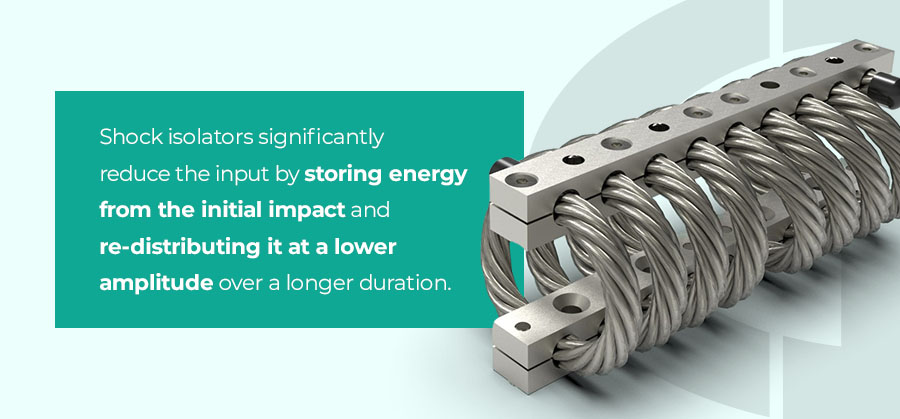

Shock isolation involves absorbing the energy of the high amplitude, short duration impulse and re-distributing it over longer durations at lower amplitudes, reducing the risk to humans, equipment or even structures. It’s critical to remember that energy is never eliminated, only re-distributed.

Shock isolation systems rely on two principal characteristics to ensure minimum transmissibility — damping and deflection capacity. Damping dissipates some energy into heat, while maximizing deflection capacity as much as is practical allows for the lowest acceleration and longest duration response amplitudes. The process consists of three elements:

- Deflect: The shock isolator responds to the shock by deflecting an amount that is defined by the shock event, the isolator’s elasticity and the inertial properties of the equipment the isolators are supporting.

- Discharge: Once the impact is stored, the shock isolating system can discharge it at a frequency and amplitude dependent on the overall system properties.

- Damping: Throughout the entire event, some energy is converted from mechanical energy to heat energy, typically through some frictional method.

Each shock pulse shape is different, defining the intensity of the shock and influencing the shock isolation system’s response. An appropriate shock isolation system takes into account the unique aspects of that shock impulse of concern in order to provide the most effective solution. During the selection of a cable isolator system, the cable diameter, the number of loops and the overall dimensions of the isolator can be fine-turned to provide an optimal response.

Shock isolation aims to ensure the shock output is significantly lower than the input by storing the energy from the initial impact.

Types of Shock Isolation

There are two principal types of shock isolation:

- Passive shock isolation: Passive isolation uses the inherent properties of springs and dampers to reduce the effects of impact shock. The spring absorbs and re-distributes the incoming impact, while the damper re-distributes the energy.

- Active shock isolation: Active isolation uses real-time measurements to dampen the incoming energy via excitation and response sensors and actuators, which produce an independent force to create a signal that neutralizes the incoming energy rather than absorbing and discharging it.

Common Materials Used in Shock Isolation Systems

Passive and active shock isolation systems have significant distinctions in form and function and thus use different materials to achieve the desired results. Common materials found in passive shock isolation systems include:

- Rubber: The viscoelasticity of rubber makes it an ideal medium for isolation and dampening. It’s a common material in isolation systems, as rubber spring elements can be optimized through complex shapes to achieve different properties across each axis. These customizations come at a cost — rubber can take a long time to prototype and manufacture if a custom solution is needed and can require regular replacement due to its natural degradation.

- Wire rope: Wire rope isolators have high shock reduction capabilities. They contain the required elasticity and damping in a compact package — comprised of helical steel cables threaded through robust retaining bars — and offer a durable, corrosion-resistant and heat-tolerant option suitable for several applications.

Active isolation systems require complex moving parts, including:

- Controller

- Piezoelectric accelerometer

- Electromagnetic transducer

- Feedback circuit

Why Is Shock Isolation Important?

Shock isolation systems are all around us — in automobiles, building structures, aircraft and other applications. Shock isolation mitigates the effect of a sudden burst of energy, protecting valuable equipment from wear or damage. Some of the principal benefits of shock isolation systems include:

- Increased equipment longevity: Shock can cause severe damage and, eventually, equipment or component failure. Isolation systems can reduce shock effects on your equipment, boosting longevity.

- Improved efficiency: Shock pulses can cause response vibrations, loosening equipment and decreasing overall performance. Shock isolators reduce equipment exposure to potentially harmful forces, so your equipment can operate optimally for longer.

- Enhanced precision: Shock can disrupt sensitive equipment calibration and cause inaccurate measurements. Applications like aerospace and medical equipment rely on absolute precision, and shock isolation helps ensure this measurement accuracy, protecting researchers, medical professionals and workers.

- Elevated safety in transport: Shock isolation systems are critical in transportation, mitigating the effects of shock to cargo, passengers and engine components and boosting safety in many transportation applications.

- Reduced costs: Reducing the effects of shock on equipment and supporting its longevity means fewer replacements and decreased maintenance costs.

- Boosted productivity: Shock can make equipment less efficient, which reduces throughput and impacts your profits. Shock isolation systems help to maintain your operations and maximize output, keeping your operations productive and boosting your bottom line.

Human safety is always a primary concern. Shock isolation can help protect human operators from injury, reducing most of the force before it reaches them. Some common shock-related injuries include:

- Bone fractures

- Soft tissue tearing

- Neurosensory injuries

- Musculoskeletal disorders

- Spinal injuries

Who Uses Shock Isolation?

Shock isolation presents a practical solution for many industries, including:

- Architecture

- Military

- Transportation

- Aerospace and defense

- Industrial and commercial

- Medical

- Manufacturing

- Construction

- Energy

- Oil and gas

When Is Shock Isolation Necessary?

Shock isolation is often necessary in motorized mechanical systems, but we encounter it in many everyday applications, from sports equipment to household items. There are two main classes of shock to consider:

- Shock indicated by a motion of support, where a shock isolation system reduces the severity of the shock for the equipment on the support.

- Shock where the forces applied to or originated within a machine — the isolation system reduces the severity of the shock experienced by the foundational support for the equipment and surrounding environment.

In any context where shock isolation is necessary, a custom solution will yield the best results. An experienced team of engineers should help you analyze your specific needs and design a system that works for your application. Consulting professionals with experience gives you confidence in your improved operation and provides a favorable return on investment.

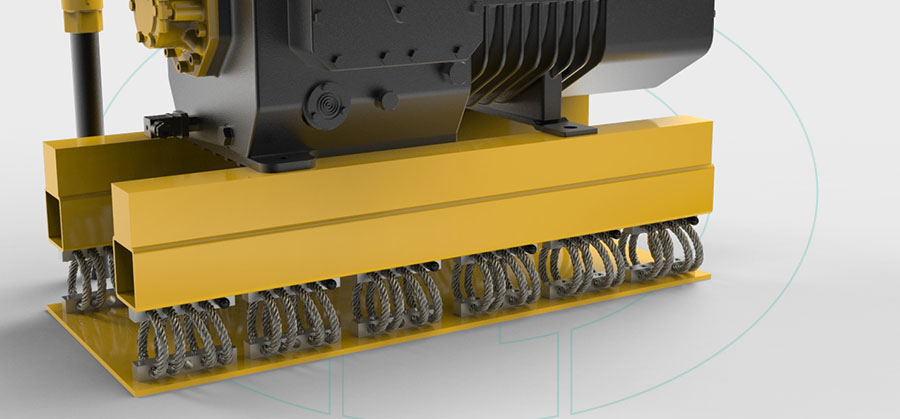

Shock Isolation Solutions from IDC

IDC offers an extensive range of shock isolation solutions for all industries. We also provide custom-engineered designs to meet your precise wire rope isolator needs. Some of our most popular wire rope isolation products include:

- M-Series: Our M-Series wire rope isolators are constructed with durable, fail-safe materials, providing a versatile and cost-effective solution for shock mitigation.

- SB-Series: Our SB-Series wire rope isolators feature a compact design with shorter bars, making them perfect for use in confined spaces.

- SM-Series: Our SM-Series wire rope isolators boast an S-shaped design, delivering outstanding support, balance, and vertical stability.

- XM-Series: Our XM-Series wire rope isolators feature a symmetrical X-shape design, providing vertical strength and torsional resistance for lighter loads.

Contact IDC for Your Shock Isolation Needs

Shock isolation is critical for effective shock management, and working with experienced engineers is the best way to improve your products and mitigate the effects of shock on your employees and systems. IDC wire rope isolators are purpose-built to provide high levels of shock protection in the most challenging environments.

We are among the industry leaders in designing, testing and manufacturing high-performance isolation systems for multiple applications. In addition to our selection of shock isolators, we develop custom solutions for your unique requirements. Contact an engineer to learn more about how IDC can help you create a safe and profitable environment.

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More